[ad_1]

3D printing is slowly becoming a part of human lives, not unlike what used to happen to mobile phones and even earlier to personal computers. But nowadays people are less often surprised by the innovations in the IT field. Many probably haven’t yet forgotten about the news covering a 3D-printed vertebra that was implanted in a living human. The time when literally printing body parts and internal organs will be possible is getting closer.

New opportunities also create new requirements for specialists.

This article won’t cover the creation of prosthetics for external organs, since it’s a separate and complex issue.

Dentistry

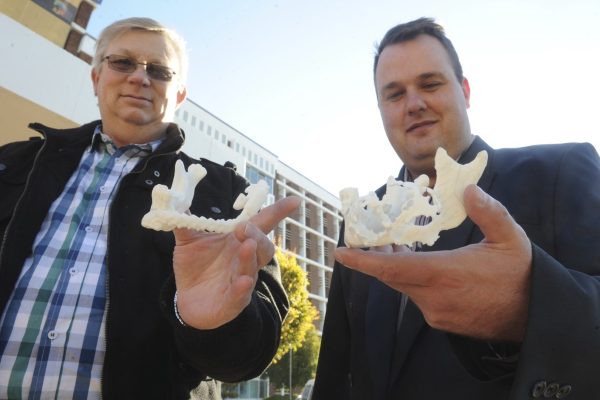

The first lower jaw implantation surgery using a 3D printed prosthesis happened in 2012. The material was titanium. It was manufactured by LayerWise.

In the summer of 2014, two more people got their lower jaws replaced with prostheses. One of them lost his jaw due to a tumor, while the other has broken it and it wasn’t possible to reconstruct.

https://Youtube.com/WOEKB2BGOvM

Dental surgeons from the Kimberly clinic.

3D printing has been used in dentistry since 1999. The pioneer of using additive technology in the dental field is the company named Align Technology, which started producing and selling mouthguards as a braces alternative.

Spine

Issues with the intervertebral discs is a common enough thing. The pinnacle of the developments in this field is surgery done on a spine of a 12 years old boy that had a malignant spinal cord tumor. The prosthesis was done from a porous material, thus the scientists think that there will be no need to change this vertebra: a tissue will grow around it and the prosthesis will become a part of a body.

The only drawback (compared to various advantages) is that recovering will take a longer time than it would be after using traditional materials.

https://Youtube.com/kVmRoYKA-Ts

Skull

Thanks to using 3D printing, 75% of a skull was replaced. This is a good number. The surgery happened on March the 4trh of 2013 in the USA. It was done after a two-week-long work with a 3D scanned skull model. The result mimics even the smallest details of the shape.

Oxford Performance Materials claims that from 300 to 500 people a month can become patients who will need similar surgeries in the USA. The numbers include the victims of motor vehicle accidents, military personnel, and oncological patients with tumors in their skulls.

Other Bones

Why is 3D printing that effective for bone prostheses?

1) Speed. Using traditional prosthesis molding technologies is a long process.

2) Low weight. It can be adjusted since the level of porosity of a titanium prosthesis can be controlled.

3) Porosity. This property allows the tissue to grow around the prosthesis.

In June of 2014, several surgeries were done in China where the patients got their clavicles, scapulas, and right ilium implanted. The surgical indications were tumors for all cases.

This is a 3D-printed scapula prosthesis.

And here is a 3D model of a pelvis in the hands of the doctors. It allowed the doctors to do the surgery faster and more efficiently.

https://Youtube.com/wqanVr9ZCQg

Joints

The first person who got their knee joint replaced by a 3D printed prosthesis got it at the beginning of 2014 in the US.

What are the advantages of 3D printed prostheses over regular ones? The difference is mainly in details: usually, for implantation, there’s a prosthesis to be found, after which the bone will be rasped to fit the prosthesis perfectly. In the case of 3D printing, the developers just designed a joint that will naturally fit this patient, based on the results of their CT scan.

This was developed by Conformis. According to Mike Myers, who is now able to walk normally and even play golf instead of stopping after every block, he doesn’t feel the presence of a foreign object in his body.

Another difference between this joint and a plastic one is that the traditional ones will have to be replaced after 10-20 years.

In 2014, the hip joint of a 71 years old woman was replaced with a 3D printed one in Britain. Titanium powder again played the role of material.

Auricle

It’s not just an auricle but a full bionic ear. But it’s not yet connected to a human.

The device made using living human cells includes an inductive antenna. It’s just a concept that will be polished over time. It was designed for testing nanoelectronics in 3D printing.

Liver

In 2013, for researching drugs, the scientists were able to print the liver tissues on a 3D printer. Hepatocytes, hepatic stellate cells, and blood vessel epithelial cells were used as the materials.

The bioprinting process.

The main issue encountered when using 3D printing for organ prosthesis is the blood supply. Each cell inside the tissues is located close to blood vessels. The issue is not yet solved.

Orthopedics

The idea is very obvious: to 3D print orthotic insoles after a scan is becoming an easy and quick process.

Surgical Assistance

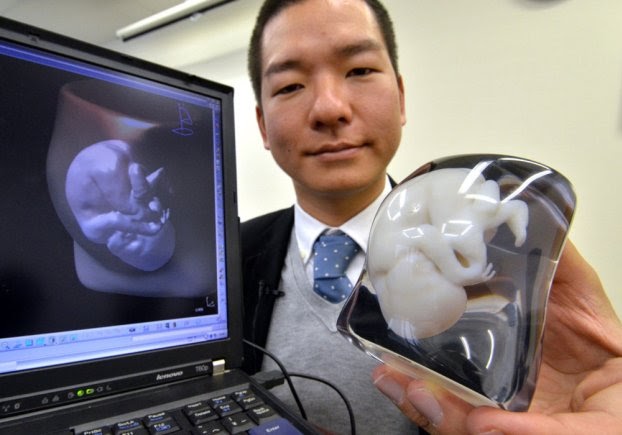

Having a 3D model, it will be easier for the surgeons to navigate inside a human body during the surgery.

Especially when the surgery is done on a little girl with a tumor that is considered inoperable. The picture shows the models of the tumor of this 12 years old girl. It’s located very close to a spine and is surrounded by healthy tissues, organs, and blood vessels. The dangerous surgery was successful thanks to the doctors using a 3D printed model for precise surgery planning.

There’s also a library of 3D models of hearts from all over the world being collected. A 3D printed heart also helps the surgeons to plan the surgery since seeing the scanning results and having a life-sized 3D printed physical model are different things.

3D printing in medicine hasn’t fully realized its whole potential. Many are sure that 3D printing organs in real time is a thing that will soon happen. Likely, in more than a decade. This will eliminate the need to wait for a donor to die in an accident leaving a heart after. The doctors will only need to do some analysis and 3D print a needed organ.

The history of 3D printing started in 1980 and is heading in this direction. And there will be new jobs and business opportunities: the companies aiming to help the surgeons, manufacture and create new kinds of prostheses, material research, and 3D bioprinting the tissues for drug testing.

New opportunities create new requirements. This is how the organ designer job in the 3D printing field was born.

Organs differ from human to human, and the damage from transplantation can be reduced by adjusting the sizes of the organs and consideration of a transplant’s unique features. If it’s possible to 3D print a new organ then it’s also possible to use the best properties of an old organ but with the problems being fixed. That means that there’s a need for a specialist with the knowledge of medicine, anatomy, and experience with 3D models and printing, who is also able to finish working on a new bioprinted organ.

[ad_2]

Source link